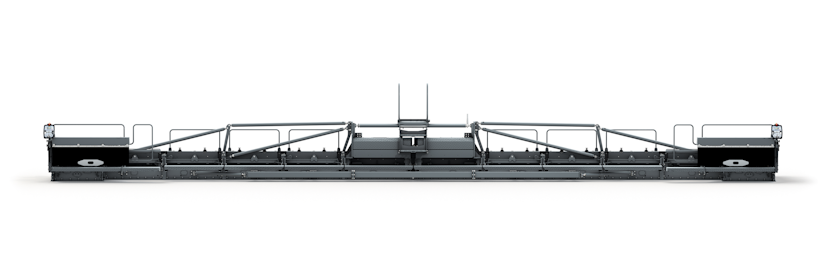

At the big Bauma construction machinery show in Germany, Vögele unveiled its biggest yet asphalt paver. The company’s flagship Vögele Super 3000-3(i) can pave widths up to 18 meters (59 feet), the equivalent of a four-lane highway without joints when used with the company’s SB 350 fixed-width screed.

To pave this wide, the Super 3000-3(i) lays down up to 1,800 tons of mix per hour. An innovative material transport system allows the height of the rear section of the chassis, the conveyor and the auger to be adjusted with the push of a button to get the mix feed coming down on the augers from above resulting an optimum head of mix in front of the screed.

As part of Vögele’s Premium line of pavers, the Super 3000-3(i) offers the company’s ErgoPlus 3 operating concept with automated features and enhanced convenience. Paving job parameters can be saved and retrieved at any time using the AutoSet Plus function for easy repeatability from day to day and job to job.

Vögele’s new fixed width screeds, the SB 350 and the SB 300, can pave base courses as deep as 50 centimeters (20 inches). The SB 350 can put down surface courses up to 5 centimeters (2-inches) thick. Both screeds are available in the TV version (tamper and vibrators) as well as the high-compaction versions TP1 (using the tamper and one pressure bar) or the TP2 (tamper and two pressure bars). The screeds are hydraulically adjustable up to 2.5 meters (8.2 feet) at the push of a button thanks to extra-wide hydraulic bolt-on extensions.

Vögele’s new Classic line, the Super 1000(i) left tracked paver and its wheeled counterpart the Super 1003(i).

Vögele also showcased two new compact pavers in the Classic line at Bauma, the Super 1000(i) tracked paver and its wheeled counterpart the Super 1003(i) for small and medium size construction projects.

Both pave widths up to 3.9 meters (12.7 feet). Instead of the ErgoPlus operating system found on Vögele’s larger pavers, the new compact models use ErgoBasic, which covers the most necessary functions and status indicators. Both pavers run on 55.4 kilowatt (74 horsepower) diesel engines. The wheeled Super 1003(i) is available as a 6×2 version or configured as a 6×4 version on request.

from Equipment World http://bit.ly/2UWk3zI

via Handy Rep Ai

Drill pipe wiper foam balls are designed to wipe drill pipe or tubing string clean of cement, fluids or debris and can be used to separate fluids in offshore and onshore oilfield services.

ReplyDeleteThe genuine MERIT makes of drill pipe wiper foam balls can be loaded into drill pipe or tubing connections.

Original WP series foam wiper ball easily passes through internal upset restrictions such as mechanical setting tools, diverters, and liner running tools and multiple balls can be pumped if necessary.

MERIT’s drill pipe wiper balls are made of natural rubber and can be used in a temperature range of 40°F (4°C) to 302°F (150°C). OEM brand new wiper ball has a parting stretch of 380 to 440%, which means it can pass through small restrictions without being damaged.

meritautomotive@gmail.com